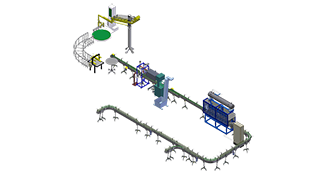

SCOUT 11A

Description Automatic canister filling installation. The unit is used to fill canisters with a volume of 1 to 10 liters with liquid products such as engine oil, concentrates, solvents, acids, aqueous solutions, etc. The installation can carry out product loading both above and below the liquid level. Filling under the level avoids foaming and the formation of an air-drop mixture of the product with the surrounding air. The installation automatically performs: moving and positioning the cans, filling the cans and tightening the lids.

| Overall dimensions WxDxH, mm | 10000х8000х2300 |

| Weight, kg | 4000 |

| Productivity, pcs/h | |

| 1000 | |

| 800 | |

| 700 | |

| Accuracy class according to GOST 8.610-2012 | 0,5 |

| The greatest limit of dispensing | 10 kg |

| Power | 220/380 В, 50 Hz |

| Pneumatic supply | 6 bar, 20 nl/min |

| Operating temperature, °C | +5…+40 |

| Protection class | IP54 |

* – Specifications may vary depending on the features of your product and operating conditions.

for your production

Use the special questionnaire to find the solution according to your

needs and parameters.

Together with you, we will find a solution, find out the details and make an appointment.