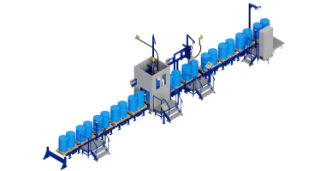

SCOUT 23A

The unit is used for filling barrels in volume from 50 to 250 liters and IBC containers of liquid products, such as motor oil, the concentrates, solvents, acids, aqueous solutions, etc. automatically. The main distinctive feature of the unit is Autonomous operation without operators, due to the use of the camera of technical vision, which allows you to automatically find the holes of the barrels ' necks and direct the loading rod to these necks. To ensure continuous operation of the installation, it is only necessary to bring pallets with empty barrels, remove pallets with filled ones and monitor the sufficiency of consumables. Opening, closing and sealing of barrels is also carried out automatically, without the participation of the operator.

| Typical overall dimensions WxDxH mm | 1300х2500х3500 |

| Used tare | 50 l, 216,5 l drums, IBC containers |

| Weight, kg | 450 |

| Productivity, pcs/h | |

| 100 | |

| 50 | |

| 15 | |

| 0.5 | |

| 5000 kg | |

| Power | 220/380 V, 50 Hz, 10-20 kW |

| Pneumatic supply | 6 bar, 80 nl/min |

| Ambient temperature, °C | +5…+40 |

for your production

Use the special questionnaire to find the solution according to your

needs and parameters.

Together with you, we will find a solution, find out the details and make an appointment.